Resources

Home

/

Resources

Understanding Automation in Engineering

Explore the role of automation in engineering processes.

Automation plays a critical role in modern engineering, particularly in industries like pharmaceuticals and manufacturing. It encompasses the use of control systems such as PLCs and HMIs to manage machinery and processes, ensuring compliance with stringent regulations like 21 CFR Part 11. By integrating automation, businesses can enhance efficiency, reduce human error, and improve data management. Automation systems include a variety of components like AC drives, CNC controllers, and servo drives, which facilitate precise control of machines. Furthermore, retrofitting existing machines with automated solutions can significantly upgrade operational capabilities and productivity. Understanding these systems allows companies to make informed decisions about their automation needs, leading to better performance and compliance.

Special Purpose Machinery Manufacturing

Learn about custom machinery solutions for your needs.

Special purpose machinery refers to equipment designed for specific tasks within manufacturing or production settings. These machines can be tailored to meet unique customer requirements, such as robotic movements, cartonators, and packing machines. For instance, horizontal and vertical packing machines are essential for efficient packaging processes, while liquid and powder filling machines ensure precision in product handling. Additionally, machinery like flaxy conveyors and line diverters streamline workflows and enhance productivity. By investing in special purpose machinery, businesses can optimize their operations, reduce labor costs, and improve output quality. Understanding these solutions helps manufacturers stay competitive in an ever-evolving market.

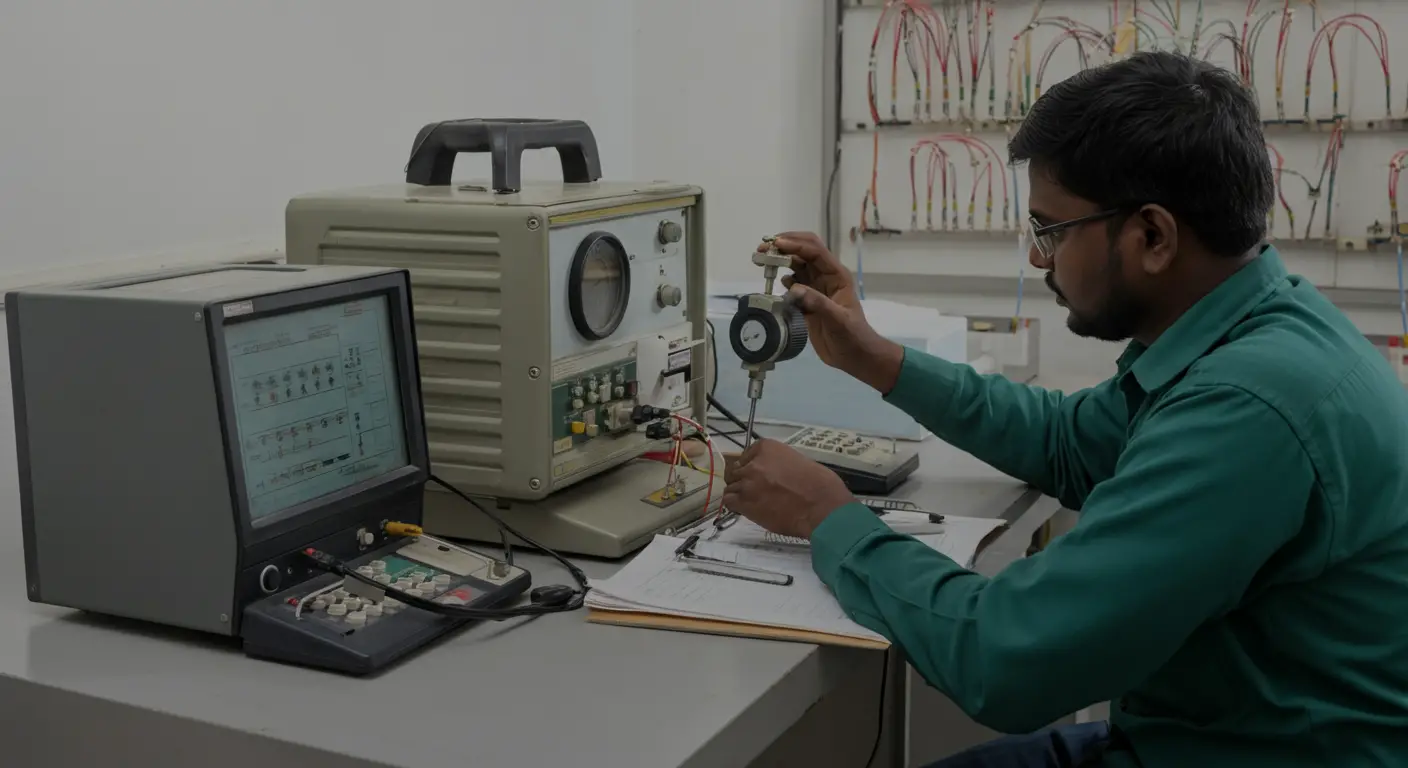

Calibration and Validation Services Explained

Discover the importance of calibration and validation.

Calibration and validation services are essential for ensuring the accuracy and reliability of instruments used in various industries. These services encompass PLC calibration, HVAC validation, and computer system validation, all crucial for maintaining compliance with industry standards. Proper calibration ensures that instruments provide accurate readings, which is vital in sectors like pharmaceuticals and manufacturing. HVAC validation ensures that environmental control systems function effectively, while computer system validation guarantees that software applications meet regulatory requirements. By utilizing these services, organizations can enhance product quality, ensure safety, and maintain compliance with stringent regulations, ultimately leading to greater operational efficiency.

Spares and Components for Engineering Needs

Find essential spares for your engineering projects.

Having access to a wide range of spare parts is crucial for maintaining and optimizing engineering systems. This includes components like PLCs, HMIs, and various types of motors and drives, which are essential for automation processes. Additionally, spares such as encoders, sensors, and electrical components ensure that machinery operates smoothly and efficiently. New technologies like proximity sensors and pressure transmitters also play a significant role in monitoring and controlling industrial processes. By sourcing quality spares, businesses can minimize downtime, reduce maintenance costs, and enhance the longevity of their equipment. Understanding the available components helps engineers make informed decisions for their projects.

Frequently Asked Questions

What are PLCs and their uses?

PLCs are programmable logic controllers used to automate industrial processes, providing precise control over machinery and operations.

How does home automation work?

Home automation involves using technology to control home systems like lighting, heating, and security, often through smart devices.

What is SCADA and its significance?

SCADA stands for Supervisory Control and Data Acquisition, crucial for monitoring and controlling industrial processes remotely.

What services do you offer for machinery?

We offer manufacturing of special purpose machines, including packing and filling machines tailored to customer specifications.

Why is calibration important?

Calibration ensures that measuring equipment provides accurate readings, essential for maintaining quality and compliance in production.

What types of sensors are available?

We provide a variety of sensors including proximity, temperature, and pressure sensors, each serving specific industrial applications.

How can I implement energy management systems?

Energy management systems can be implemented through solar solutions and load reduction strategies to optimize energy use.

What is HVAC validation?

HVAC validation ensures that heating, ventilation, and air conditioning systems meet regulatory standards and operate efficiently.

How often should calibration be performed?

Calibration frequency depends on the equipment and industry standards but is typically recommended annually or biannually.

What are the advantages of using servo drives?

Servo drives provide precise control of motor speed and position, enhancing performance in automation systems.

Get a Free Quote

Fill out the form to receive a complimentary consultation and discover how our solutions can benefit your business.